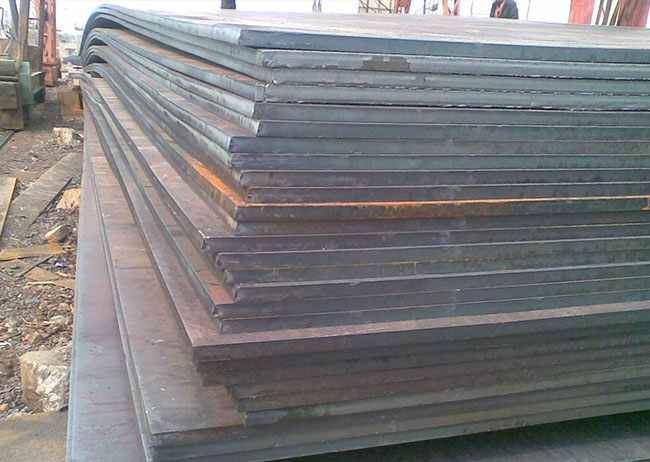

Control of surface crack defects of a special steel plate

Date:2015-08-31 / Popularity:

Especially thick steel plate is a steel plate with a thickness greater than 50mm, and it is easy to appear because of the surface cracks caused by continuous casting billet. In particular, it is very clear that the surface crack is very small and the surface cracks are very small. Stainless steel in the casting process of the thickness of the thickness of the main thickness of 80mm, 120mm, 200mm, etc.. The control measures of the special thick sheet cracking are as follows:

1, control the liquid level of the liquid crystal

Controlling the liquid level of the liquid crystal is stable, and the fluctuation of the liquid crystal is controlled by mm (3-5).

2, control of the molten steel heat and continuous casting machine

The high temperature of molten steel and the fluctuation of drawing speed of continuous casting machine will have a significant effect on the formation of corner crack of continuous casting slab.

3, control the mold taper

The larger the taper of the mould, the greater the friction force between the mold and the continuous casting billet, the stress concentration in the corner of the continuous casting billet, the crack and the extension.

4, improve the water quality of the mould cooling water

The mold cooling water hardness can cause the mold copper plate in the sink, the serious fouling, resulting in the uneven cooling of the shell and the internal stress, which leads to the continuous casting billet. Test frequency of cooling water for the mould.

5, the use of the system of weak cold

The weak strength of the mold cooling system is conducive to slow down the heat transfer of the mold, reduce the thermal stress of the shell, so that the surface quality of continuous casting billet can be effectively improved.

6, optimize the two cold system

For thick slab, the weak cooling system should be adopted to ensure the temperature of the plate, and the second is to ensure the cooling uniformity of the spray nozzle, which can ensure the surface temperature of the continuous casting billet in the two cold region. Production time to maintain constant speed operation, reducing the casting billet surface cracking.

7, improve the mold flux properties

Increasing the temperature and viscosity of the slag can improve the lubrication of the slag film and the continuous casting billet, and reduce the friction between the mould region and the continuous casting billet.

Edit:Admin